Centrex Technical Sales is a value-added fabricator and supplier of engineered equipment and commodity materials to the Pharmaceutical, Chemical, Food and Beverage industries. Centrex focuses on providing technologically superior equipment coupled with expert sales support and service to its customer. Centrex is the premier provider of products and services in its territory. Over the past 17 years, it is Centrex’s goal to exceed customers’ expectations. Centrex prides itself in finding solutions to process needs and is capable of manufacturing turnkey solutions or custom design. Centrex understands the benefits of skidded pre-fabricated modular systems in minimizing operational interruption. Skidded systems can be built and tested in a controlled environment giving customers economical solutions to meet project timelines and budgets.

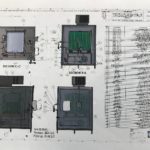

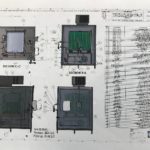

Design: Centrex’s Engineering team uses the latest addition of SolidWorks Professional software to provide customers a 3D model prior to releasing for construction. The Centrex team has years of experience in, not only design, but trouble shooting and finding solutions in the ever-changing sanitary process and industrial market.

Welding: Centrex has a team of Certified welders who take pride in their art. Whenever possible, welds are made with an automatic computer controlled orbital welder. Sanitary welds are done using cryogenic argon stored in bulk tanks distributed through polished stainless-steel distribution piping network. Welds are visually inspected or borescoped to insure quality. Piping systems can be hydrostatic tested using DI water from a filtration skid.

Polishing: Centrex polishing is done in a segregated polish shop with filtered downdraft tables. Centrex has simi-automatic polishing machines designed to polish both ID and OD of pipe and tube. Centrex has a multitude of manual polishing equipment to polish from large tanks to the smallest fittings. Centrex can electro-passivate as well as provide certified electropolishing.

Fabrication: Centrex offers extensive machining capabilities utilizing the following equipment: automatic band saw up to 12”, hi-definition plasma table for fabricating stainless steel up to 1” thick, milling machines, lathes, punches, sheer and break. All of our tools are dedicated to stainless steel or more noble alloys only.

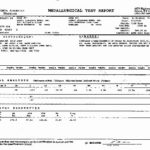

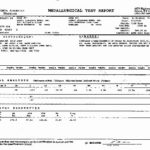

Material Control: Centrex represents some of the most highly-respected manufactures in our industry. All materials are checked in to confirm project specifications. Centrex has an electro-etching machine to mark parts with part number if required. Certificate of Compliance and or Material Test Reports can be provided for all pipe, tube and fittings if required.

Electrical: Centrex electrical team is headed by a master electrician who oversees the segregated electrical panel shop. UL can be provided upon request. Centrex can design and program numerous systems using the latest equipment from Allen Bradley, ABB, IFM, Lenze, Maple Systems or customer project requirements.

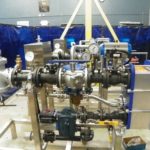

Quality Control: Centrex inspects all skids prior to shipping. Centrex has 3phase electrical test stand complete with flow meters, DI water system with 350 gallon tank, temperature and pressure transmitters, and a 4-20 mA process simulator.

Material Handling: Centrex’s 15,000-square foot manufacturing plant has two 5-ton overhead bridge cranes the length of building as well as a JCB 508C 8000 pound lift.

Hose Assembly: Centrex is certified by Ace Manufacturing as a 3A Certified hose assembly center. Centrex stocks a wide range of rubber, Teflon and silicone hoses to meet the needs of the sanitary industry. Centrex has an isolated hose assembly shop to crimp hoses from ¼” to 4”. Centrex offers Centrex-Flex 6500 a chlorabutal-lined rubber hose designed for the food and beverage industry in a wire reinforced suction discharge hose as well as in a crush resistant hose. Centrex offers a variety of stainless steel end connections including: Tri-clamp, Bevel Seat, John Perry, Din, SMS, RJT, ANSI Flange, Male NPT, Female NPT, JIC and OD Tube ends.

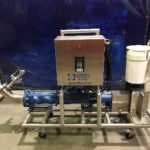

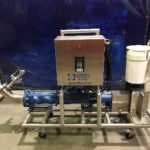

Pump Assembly: Centrex is a Master Pump Center for Alfa Laval / Tri-clover. Centrex keeps a large stock of sanitary pumps ready to ship within 24 hours. Centrex builds specialized pump bases and carts to include PLC’s, VFD’s, flow meters, pressure switches and other electrical controls. Centrex also rebuilds and modifies pumps for our customers.

Valve Manifolding: Centrex specializes in constructing custom sanitary valve manifolds. Manifolds are designed to the highest hygienic standards, ease of maintenance, compact design and the highest process quality to insure product integrity.

Repair Center: Centrex is a Master Repair Center for Alfa Laval. Centrex factory trained technicians rebuilds all brands of Sanitary Valves, Pumps, Tank Cleaning devises and other sanitary process equipment. Centrex reconditions to factory specifications including replacing parts, polishing, machining and painting.

Before & after repairs

Custom Sanitary floor drains: Sanitary polished stainless-steel solutions for disposal distribution.

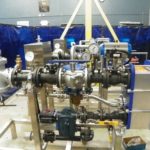

Process Skids: Let the Centrex Sales and Engineering team find a custom solution to lean and improve your manufacturing process and product. Centrex specializes in solutions for the Food and Beverage industry.

CIP / COP Systems: Centrex understand the necessity of a hygienic process system. Centrex can custom design a Single tank or multi-tank fully automatic or semi-automatic CIP (Clean in Place) or COP (Clean out of Place) system. Centrex can custom design PLC operated systems to meet your specific needs whether cleaning kegs, parts, hoses or pipeline.

Heat Transfer skids: In almost every plant, there is a need to heat or cool. Centrex has developed custom solutions to all of these needs from simple steam to hot water sets to more advanced scrape heat exchanger packages. Centrex has teamed up with some of the most advanced manufactures of heat exchangers in the industry to find a solution. Centrex will package as a system complete with controls.

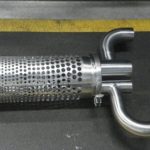

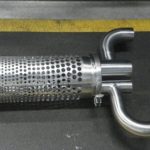

Custom Filter Skids / Housings: Centrex not only represents, but partners with sanitary filter / strainer manufactures to custom build applications.

Custom Tanks: If you are looking for a 70,000-gallon Silo or a 1-gallon portable tank, Centrex has you covered. Centrex represents three of the largest sanitary tank manufactures in the USA, as well as manufacturing up to 5,000 gallon custom tanks.