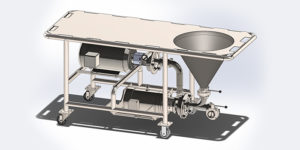

Ampco’s Applied Products POWDER-max reduces processing time and provides optimal product consistency with no batch size limitations. An innovative design allows PM Powder Mixers to quickly blend wet and dry ingredients in a single, fully portable unit.

Powder Max Brochure

Powder Induction Flyer

AAP Full Line Brochure

Full Sanitary Line Brochure

Model SP Liquid Ring Pump

Model SBH Shear Blender

304 Stainless Steel Base Material

316L Wetted Parts

Dual Motor Starter – NEMA 4X

Stainless Steel Casters

Powder Control Valve

Fluid Control Valve

The system is designed to induce powders at a highly efficient rate with minimal shear. The Ampco SP Series pump powers this unit and the self-priming SP provides the suction for the induction process.

AAP Full Line Brochure

Full Sanitary Line Brochure

Powder Induction Flyer

Model SP Liquid Ring Pump

304 Stainless Steel Base Material

316L Wetted Parts

Motor Starter – NEMA 4X / VFD Upon Request

Stainless Steel Casters

Powder Control Valve

Fluid Control Valve

DRY-blend system offers efficient and thorough blending of wet and dry ingredients.

A tube within a tube design – powered by the Ampco AC+ centrifugal pump – eliminates foaming, lumping and fisheyes, and delivers consistent blending with every batch.

Dry Blend Brochure

AAP Full Line Brochure

Powder Induction Flyer

Full Sanitary Line Brochure

AC+ Centrifugal Pump

316L Stainless Steel Wetted Parts

Customizable, Carts, Tables, Belt Drive with Base, Controls

Easily Integrated into Existing Process Systems

The SHEAR-blend portable table top hopper system is designed for ergonomic small batch blending. All product contact components are made of 316L stainless steel. Although the footprint is small, the power behind the SHEAR-blend system is not.

SHEAR-blend Brochure

AAP Full Line Brochure

Powder Induction Flyer

Full Sanitary Line Brochure

Combination Integrated Impeller and Dynamic Shear Teeth

Pump and Blend in a Single Stage

Cast and Machined

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

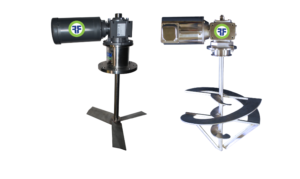

Ampco Applied Products offers two shear blender model series: SBH/SBI. Applications range from pharmaceutical to food, industrial to chemical … and everything in between.

SBH/SBI Brochure

AAP Full Line Brochure

Powder Induction Flyer

Cellar Cart SBI-R00 Flyer

Full Sanitary Line Brochure

High Shear Levels

316L Stainless Steel Heavy Wall Construction

Cast and Machined

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

The ultimate in high shear mixing and dispersing, meeting the tight tolerances required in high shear applications while maintaining extremely efficient flow.

SHEAR-Max Brochure

AAP Full Line Brochure

Full Sanitary Line Brochure

Powder Induction Flyer

Combination Integrated Impeller and Dynamic Shear Teeth

Pump and Blend in a Single Stage

Machined from 316L bar stock

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

Ampco’s in-tank mixers are used to hydrate, dissolve, homogenize, disperse and emulsify products consistently and efficiently covering a wide range of applications in food, chemical, and pharmaceutical industries. The multiple interchangeable stainless steel work heads are designed for 3A and CIP.

JET-shear Flyer

AAP Full Line Brochure

Full Sanitary Line Brochure

Powder Induction Flyer

Emulsion to less than 10 microns

Max volumes up to 1000 gallons/ 3875 liters for self-mixing

Stainless steel mixer shaft

Multiple 316 stainless work head styles available

Mixing heads can be interchanged

Designed to 3A

CIP-able

Multiple mounting configurations