FDA, 3A*, USDA, PMO, EHDGE and most HACCP plans state that it is your responsibility to test your plate style heat exchanger at least once a year to safeguard against cross contamination. Thermaline introduces the most comprehensive testing procedure and plan on the market today that meets or exceeds the regulatory requirements.

The CCT (Cross Contamination Testing) is a patented test process that is easy to use, easy to understand and the results are invaluable.

Not every plant is the same therefore the CCT program is based on your needs.

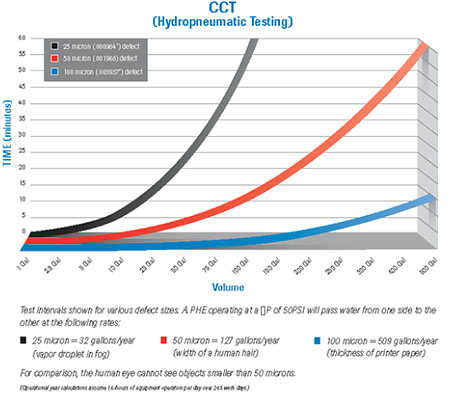

Both the CCT 1.0 and 2.0 are patented primary testers that operate on the same basic hydro-pneumatic principle. Pressurized air is introduced on one side of the PHE is there is an internal defect pressure builds in the ambient side and is sensed with the CCT. Primary testing tests the plate pack as a whole for defects, nor the individual.

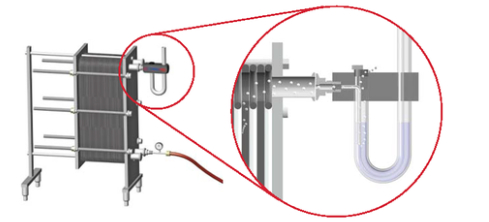

CCT 1.0 is a visual test method that can be performed by your technicians or a QA personnel. A defect is immediately sensed by the CCT and is visually seen as a bubble in the downdraft tube.

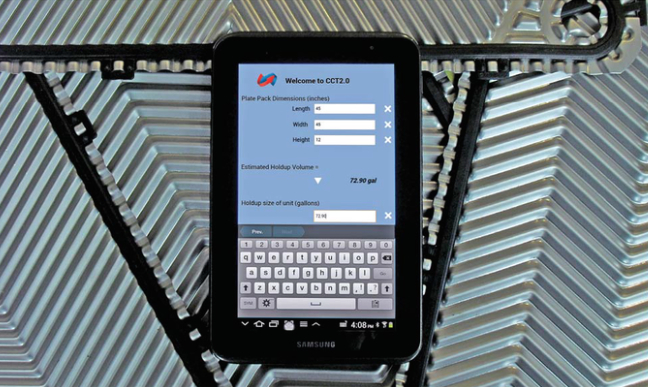

CCT 2.0 calculates the relationship between volume, pressure, temperature and time to determine if a defect exists and defines the severity so you can make an informed decision on an action plan. Documents the test and surrounding environment, creates a report, sends you a copy and automatically adds the report to the history of the unit accessible with the QR program or accessed on line. Operates on Android, Apple and Microsoft platforms.

Thermaline’s patented CCT (Cross Contamination Tester) is a primary test used to test an entire plate pack or tubular system for internal defects that can cross-contaminate your product.The CCT uses hydro-pneumatics to sense a defect and inform you of the severity of the defect so you can make an informed decision as to how and when to address the problem.

The CCT is a first line of defense, alerting you to potential unseen issues in your heat transfer systems and helping you prevent contamination from occurring. Your equipment does not be disassembled and plant down-time is minimized, generally to a fraction of the downtime incurred by other testing methods.

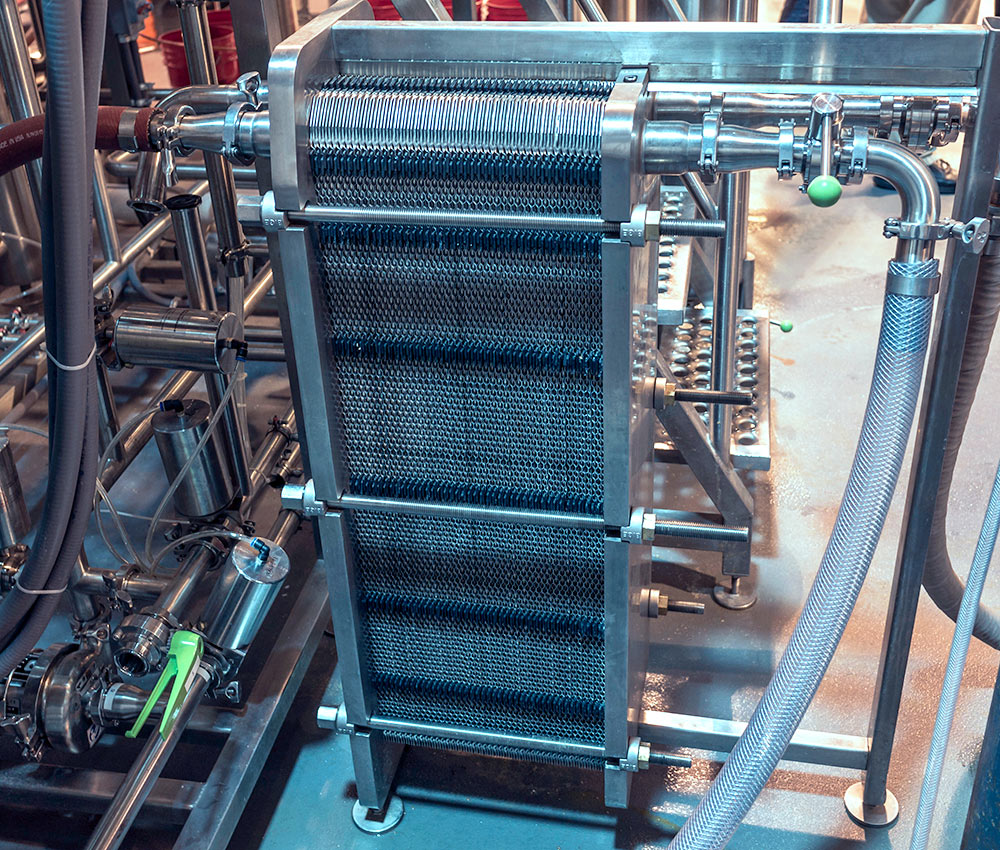

Plate, shell and tube, and tubular heat exchangers use one fluid to heat or cool another fluid indirectly without mixing the two fluids, the fluids should never come in contact with each other. Visit our informational videos to better understand the operation of a heat exchanger.

A heat exchanger can develop internal or external leaks. If external, the leaks are evident immediately as you will see fluid leaking to the ground. However, internal leaks usually gradually develop over time and give no visual indication at the heat exchanger that they even exist.

CCT or Cross Contamination Tester is a primary test used to test an entire plate pack for internal defects that can cross contaminate your product. Patented Thermaline CCT uses hydro-pneumatics to sense a defect and inform you the severity of the defect so you can make an informed decision as to how and when to address the problem.

A heat exchanger consists of two sides(we’ll call them side A and side B for now). Regulated plant air is introduced to a port on side A of the heat exchanger. The CPU is attached to the opposite port of side A. The CCT is connected to side B port and the opposite port to side B is capped.

The CCT is capable of performing a visual test as well as a calculated test.

Once the CCT is installed the visual test is automatic. If a defect exists air will pass through the defect from side A through to side B which raises the atmospheric pressure of side B which results in bubbles in the tube.

Using a correlation between time/volume/pressure and defect size, you will be provided with a defect size should the CCT detect an issue, allowing your company to assess the severity of the defect.

We put BandAids on cuts, drink coffee out of Styrofoam cups, put notes on Post Its, and use Bubble Wrap to ship things. All of these are brand names commonly used to describe a general concept.

When it comes to testing a heat exchanger cross contamination and internal leaks the industry calls this dye testing. Although dye testing is not a specific trade name it is a misleading description that indicates dye is the only way to test for cross contamination; This is far from the truth!

Dye testing was one the original methods of testing since its introduction to the industry there have been many developments in testing heat exchangers. FDA, USDA, 3-A and other regulatory agencies do not specify that a heat exchanger be dye tested rather they specify a heat exchanger be tested with a method capable of detecting an internal leak.

Most tests today test the entire plate pack as a whole (also know as a primary test). If a heat exchanger passes a primary test then there is no need to do further testing. If a heat exchanger fails a primary test then dye testing is one of the methods used in a secondary test to pinpoint a leak.

For many years and even to this day some companies use dye testing as a primary test. This type of testing is not only time-consuming, expensive, and messy but difficult for a trained technician to perform with the elevated attention needed to interpret the dye test results correctly. This can lead to thousands of dollars lost chasing down problems that may not even exist.

Thermaline’s patented CCT program is setting new standards in the way heat exchanger testing is performed. Finally, there is a test that is comprehensive and cost effective with a program that fits your testing needs.

Courtesy of Thermaline.com

3A-FDA-USDA-PMO-FSMA-CFIA have established mandatory guidelines to test Heat Exchangers for internal plate defects using a validated test procedure. Thermalines Patented CCT 4.0 Tester provides documented results of the test and is easy to use requiring only electricity and plant air to operate.

A factory trained technician travels to your facility and tests your heat exchangers, provides you with compliance documentation of the results and advises further action if needed. Price varies with number of units tested per visit, travel expenses, pipe removal/installation. Weekend, Holiday and Standby rates apply. (Inquire for details)

Average CCT test by a Factory Trained Technician ranges from $2000 – $4000 per visit for 2-8 heat exchangers.

Save Time and Money with the Right Testing Plan.

Call and ask for an estimate at 844-544-1706.