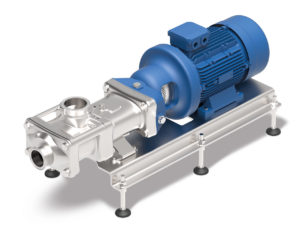

Wangen Twin Screw Pump

The new generation of the WANGEN Twin screw pump is part of the hygienic pumping solutions from WANGEN and was designed to reliably pump low to highly viscous, volatile or gaseous products and for applications where maximum hygiene and efficiency is required.

- Spindle change without re-synchronisation of the spindle shafts, enabled by WANGEN PUMPEN’s fast-X-change® technology.

- Seal change simple and fast as a result of cartridge construction design.

- Alignment of the coupling by a self-centring flange housing (lantern optionally available). As a result, no re-alignment of the coupling is needed, e.g. after service activities.

Technology/Details

- Service-proven sealing systems

- flexible drive selection

- ground, electropolished surfaces

- large variety of flange connections

- Various mechanical seals as standard versions

- CIP (Cleaning in Place)

- Easy cleaning thanks to construction with little dead space

- Rpm (rotations per minute) range from 100 to 4.000 min-1

- Lip seal, single-action mechanical sealsor double-action mechanical seals

- Surfaces of the parts in contact with the product: Ra < 0,8 μm

- Materials in contact with the product: stainless steel 1.4404

- Priming capacity with NPSHR < 2 m

- Viskosity range from 0,5 to 1.000.000 mPas